Home / Products / High Voltage / HV Passive Components / Connectors / Customized HV-Connectors

How to get your own High Voltage Connector

Even with our wide portfolio we cannot always satisfy all expectations and functions. Especially in the world of high voltage applications the uncommon is part of everyday life and often enough the suit won’t fit “off-the-shelf”. Over the years we have provided several customer specific projects from exclusive designs and developments to application specific adjustments and modifications for companies or scientific institutions.

A few examples are:

- 3-pin 60 kV-Connector for Electronbeam Lithogrphy

- 2-pin 3 kV-Connector for thickness profile measurement for the steel industry

- 2-pin 24kV-Connector with signal-control pins for a medical application

A costumer specific solution often is less expensive than often expected. We assist you to find the optimal solution for your problem – and the most suitable and functional solution mostly is also the cheapest, most effective and most sustainable on the long term.

Download our technical questionnaire to explain your requirements, we’ll be happy to assist you.

Customized Modifications

By modifying our standard connectors, we are able to offer customized versions for your specific needs. Together we prepare and develop the optimal configuration for your application. | Customized Design

Because of high complexity, specific environmental conditions or other reasons your application might require the design of a new connector. Customized designs guarantee the best possible functionality and cost-efficiency. |

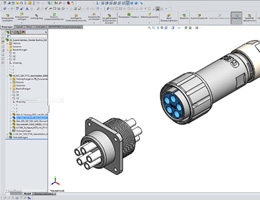

3D-design in Solidworks

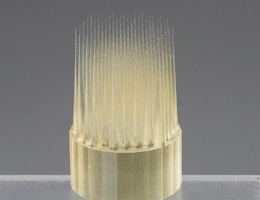

3D CAD design is the perfect starting point for NC programming, mold design, metalworking and prototyping. Several years ago, we changed from 2D to 3D-design, since this offers advantages such as significantly improved visualization and representation, better design and customer communication, interference and collision checking, associativity and modifiability, virtual testing and optimization as well as the easy creation of exploded views, technical illustrations and assembly instructions. | Rapid prototyping and 3D-printing

The investment into modern high-resolution prototyping by 3D-print also was primarily made in to avoid weeks of waiting periods for STL parts and significantly accelerate the design process for our customers. The ability to replicate a highly precise and functional (!) prototype, provide it to the costumer for examination and easily rework it means a huge time saving and simplification for those involved. |