Home / Products / High Voltage / HV Active Components / Solid-State Switches / A Current depending on-time, Thyristor / SCR

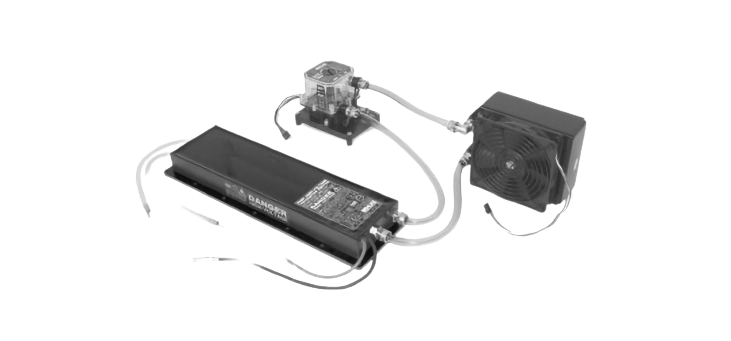

DLC - Direct Liquid Cooling with non-conductive coolants

Best cooling efficiency of all known cooling methods ● Allows an extremely compact high voltage switch design in connection with excellent Pd(max) specifications ● The absence of grounded heatsinks minimizes the stray capacitance with the result of faster electrical rise time and lower power losses at high operating frequencies ● The DLC principle allows a very homogenous cooling of the entire electronics of the switching module and reduces significantly the thermal stress at cyclic load change.

Technical Note: Behlke DLC cooling systems can be operated with GALDEN or any other similar PFPE / PFC / HFE heat transfer fluid. A cost efficient alternative to the PFPE / PFC / HFE coolants is the low viscose sillicone oil WACKER AK 10 (chemically compatible to all materials of BEHLKE DLC switches). Mineral transformer oils are partly not compatible to BEHLKE DLC systems. Please consult BEHLKE for more information regarding transformer oil restrictions.

Pump Units

Intelligent Pump Unit with coolant reservoir and built-in control electronics for the pump motor and possible external radiator fans. Highly reliable design for professional purposes. The pump housing / reservoir is milled from a billet aluminum block and allows an absolute leakage free operation also at high temperature and high pressure. The front side of the unit, which is usually mounted behind the front panel of a system housing (e.g. a 19 inch housing unit), has an o-ring sealed viewing window for the built-in flow turbine wheel. The flow turbine wheel serves as a visual flow indicator and as digital flow sensor in the same time. Double ball bearing in connection with optical scanning guarantees a MTBF of several hundred thousand hours for this safety relevant part component.

DLC Cooling Boxes

Pressure proof cooling boxes for the integration of non-DLC components, such as classical power electronic components and peripheral circuit boards, into a DLC cooling system. The standard cooling box program is based on a 40 mm grid. Any x-y enlargement can be realized in steps of 40 mm up to the maximum available length (inner dimension 944 mm, outher dimension 974 mm, see data sheet for detailed information). Customized DLC cooling boxes in any dimension up to 1000 x 750 x 120 mm³ with any kind of electrical feedthrus in any position are available. Please contact us for further information. The cooling boxes have an inner height of 25 mm (1”) and are ideal for printed circuit boards. The inner height can optionally be increased or reduced. The housings have at least 3 threaded holes G1/4 on each side (only 2 on the front / rear side for size A…). The G1/4 threads are used for the hose connectors and for the electrical standard feedthrus. Two hose connectors and screw caps are included in the supply. Electrical feedthrus must be ordered separately. The standard housings are made from Delrin and Makrolon. PEEK, PVC and Aluminum are optionally available.